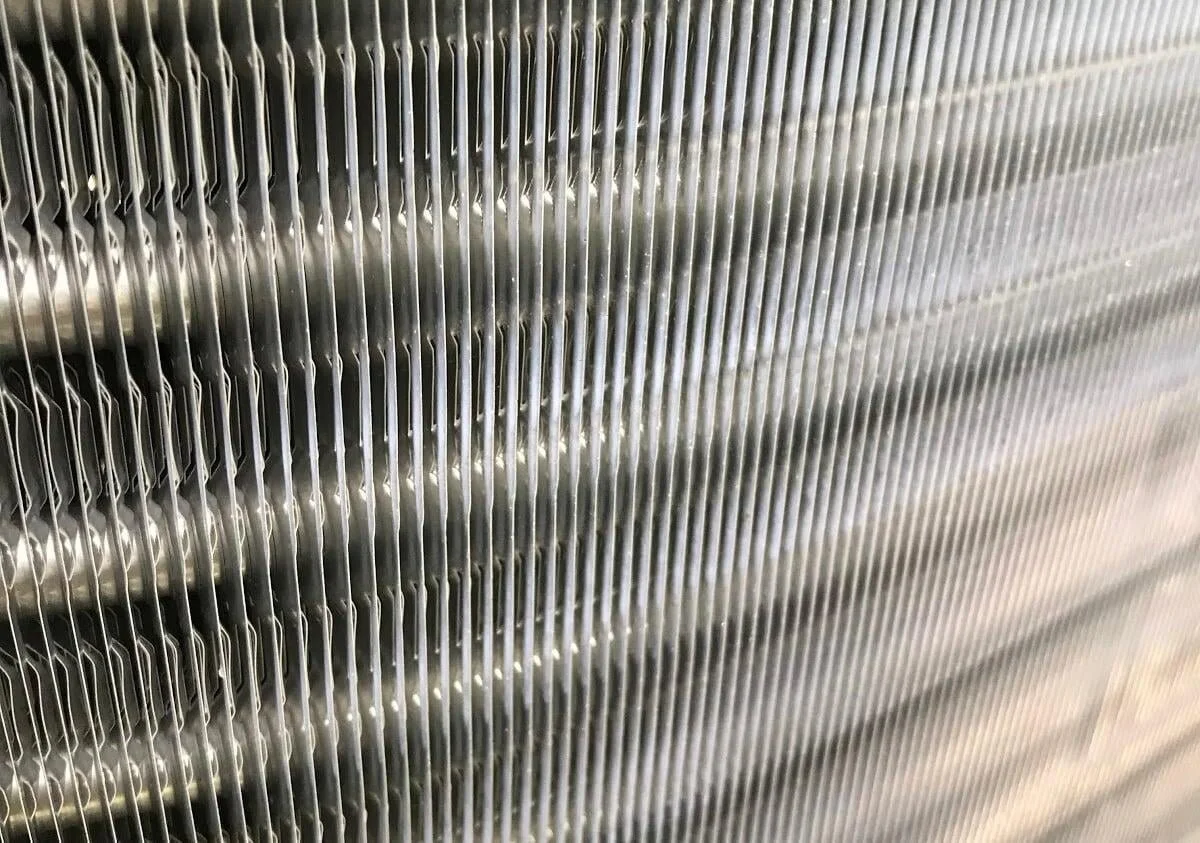

We are the anti-corrosive coating solution for HVAC

📈Increase Efficiency

Reduces air conditioning energy cost up to 15%

The return on your investment will be achieved in 10-18 months for HVAC units treated (energy costs alone).

Increases the life of new or used units

Friction is reduced on treated surface

Increases laminar airflow across the coil and improves the capacity of condenser units to offload heat

🔬 Inorganic Coating

Silicon-ceramic coating designed to bond on the molecular level with metal substrates

Inorganic coating (does not permit microbial growth) won't oxidize

Virtually impervious to moisture, UV, acids, alkalis, and biological contaminants

Covalent bonding between the proprietary coating and the substrate is nearly unbreakable

☂️ Corrosion Resistance

Controls corrosion and stops all degradation of treated units

Seals and protects all noble metals, plastics, electrical components, and even the control panels and logic boards

Hydrophobic finish is virtually impervious to moisture, UV, acids, alkalis, and biological contaminants

Stands up to the hottest and most corrosive environments including coastal salt-laden air, industrial acid rain, high-alkalinity, chemical attack, UV radiation and abrasion

Dry temp max is 800 degrees Fahrenheit.

🏆 Full Coverage

The entire unit is coated including the inside and outside of the cabinet, tubing and electrical components

Can be correctly applied in high humidity environments

Can be applied in the field on existing units

A single treatment will preserve coils and components for the mechanical life of the HVAC unit

Once cured, is FDA certified for food preparation surfaces

Dry film thickness of 0.5 mils (12.7 microns)

INFINIGUARD® protects HVAC equipment by modifying the surface of exposed metals and encapsulating treated units with an ultra-strong, flexible, thin clear ceramic layer of siloxane. Once treated with INFINIGUARD®, equipment maintains like-new efficiency and is much easier to clean and maintain.